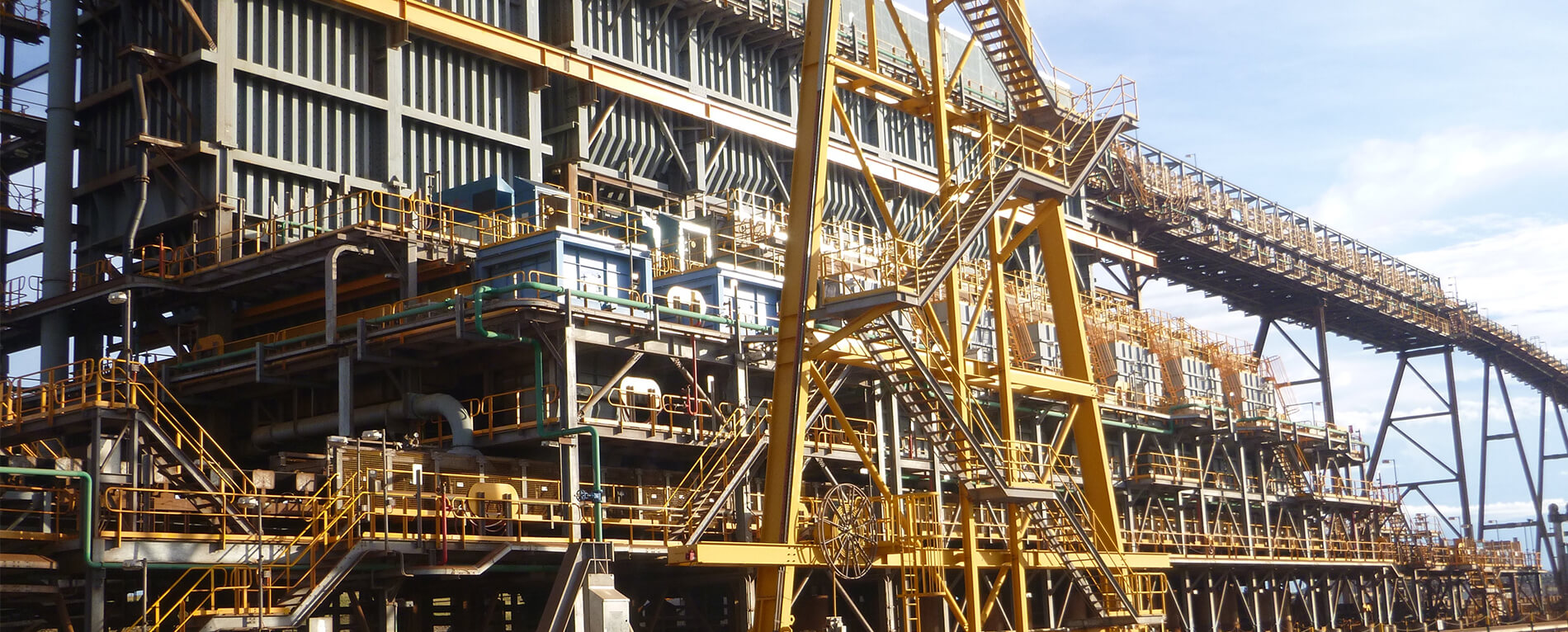

JOEST Vibration Technology utilised in plant upgrade for Pilbara iron ore producer

JOEST Australia Pty Ltd recently supplied two JOEST Vibrating Grizzly Screens (1 x Primary and 1 x Rotable) to Roy Hill Iron Ore Pty Ltd for their iron ore plant in the Pilbara region of Western Australia. JOEST Australia Pty Ltd is a world leader in the supply of vibration equipment for high capacity mineral processing applications. JOEST Australia Pty Ltd is a subsidiary company of, JÖST GmbH + Co. KG of Dülmen, Germany.

The Vibrating Grizzly Screen is designed to handle up to 4300 Tonnes Per Hour of iron ore and caters for a maximum particle size of 2400mm x 1450mm. The Vibrating Grizzly Screen is a mechanical screening device and is utilised to separate large particles from a smaller fraction in order to allow each size fraction to be treated downstream in the process. In this application material from the Run-Of-Mine bin discharge apron feeder is fed to the Vibrating Grizzly. The Vibrating Grizzly Screen undersize discharges material to a conveyor and the oversize is discharged directly into the Primary Jaw Gyratory Crusher.

This significant project reflects JOEST Australia’s proven capability and experience in delivering a reliable solution to the industry and now the Roy Hill Mine Site. This unit is the first JOEST Grizzly for the Roy Hill operation and adds to JOEST Australia’s growing list of worldwide installations.

The robust construction and user-friendly maintenance features offers an effective solution for treating large tonnages with the benefit of cost-effective plant design and simplicity of operation. The Vibrating Grizzly will be operational before the end of 2020.