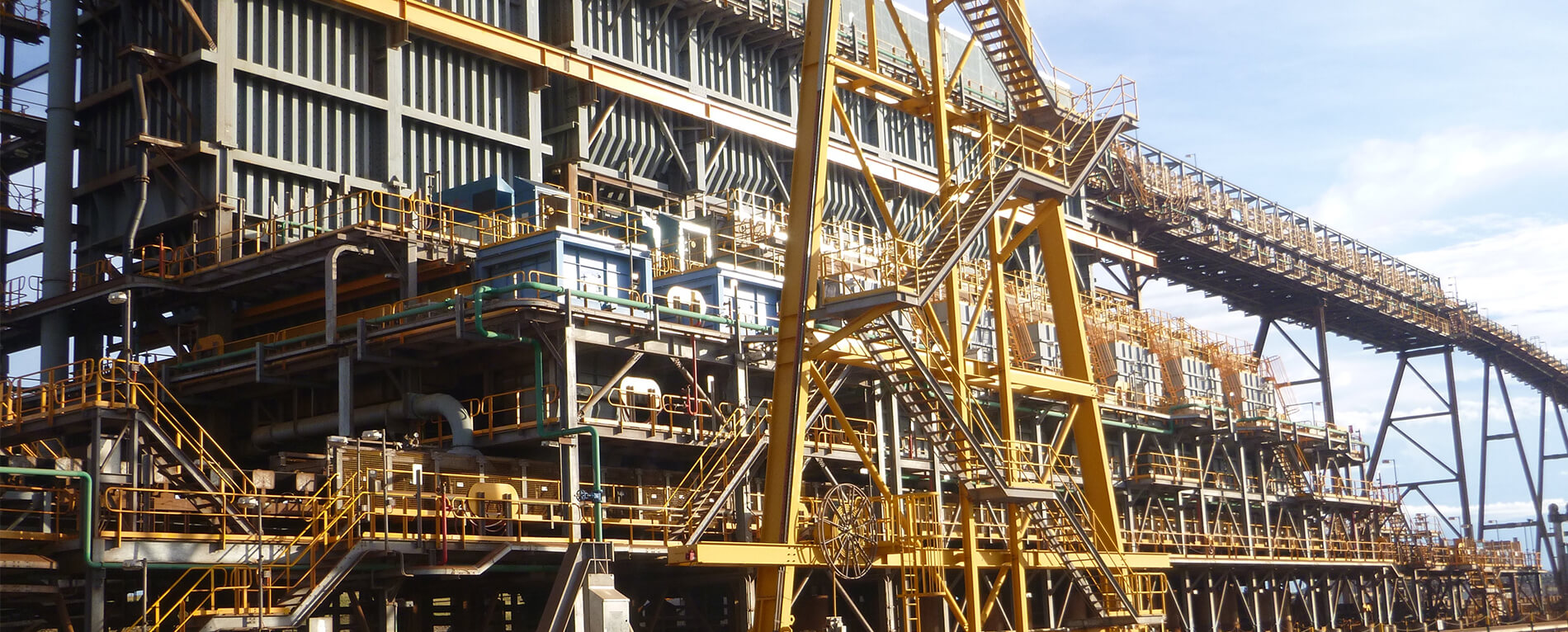

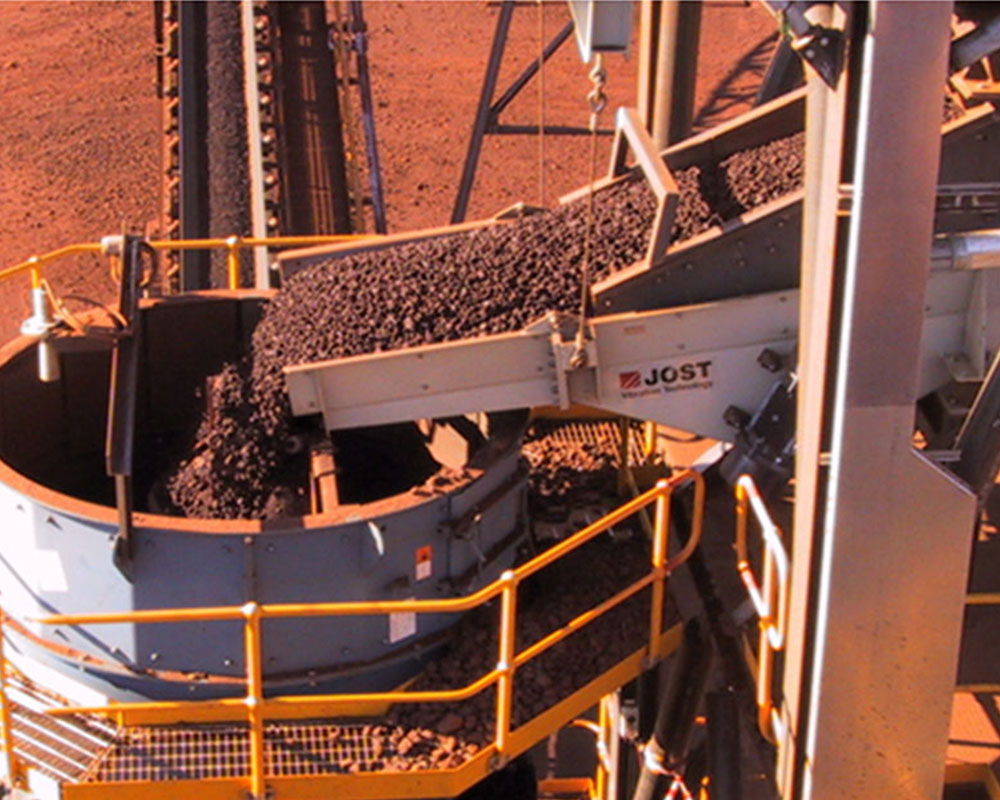

Feeding

Hopper discharge feeders are special discharge devices for a wide range of bulk materials from hoppers and silos.

Two self-synchronizing counter-rotating JÖST unbalanced drives are attached to a trough machine body, which they excite via a linear oscillating movement. This conveys the bulk material by means of micro projection movement and discharges it from the hopper. With this type of design, very high discharge rates can be achieved. Various parameters have to be considered in the system’s design and configuration, such as hopper pressure, hopper geometry, particle size, flowability, humidity, and tendency to caking. Hopper discharge feeders are therefore designed individually for each application.